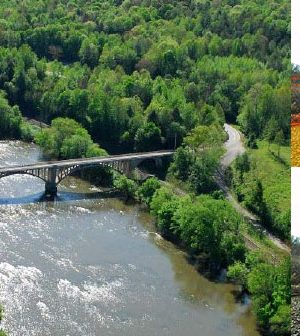

Due to age-related deterioration, the Historic Wolf Creek Bridge is undergoing a major rehabilitation. At 556 feet long and 24 feet wide, the bridge was completed in February 1928 at a cost of $119,102.41. The bridge has been repaired several times, but the Wolf Creek Bridge Rehabilitation involves the complete removal of the bridge deck, the demolition of all spandrel bents, the removal of both abutments and the hydro-blasting of all three arches. All of the reconstruction must match and be based on the foundations of the remaining and rehabilitated items, thus the contractor is required to build the bridge back to its original form. The piers, the arches and the spandrel footings, which attach to the top of the arches, are the only components to remain.

This project provided several challenges since there are no as-builts of the existing piers, arches, spandrel bents or abutments. Additionally, all elevations and locations needed to be calculated based on the existing foundations and arches. The job required the calculations of the top of deck grades, beam-seat grades, spandrel-column grades, pier grades and abutment grades. To achieve this high level of as-built accuracy from an 80-year-old structure, Wilson & Associates decided to use ground-based LiDAR or “laser scanning,” allowing us to as-built the structure without physically accessing the location of each point of data. Using a laser scanner would give us a greater redundancy of measurements to insure that the bridge would match the existing foundations. A typical ground-based survey, using traditional techniques, would have yielded about 200 to 300 points of data. The laser scanner provided more than 21 million points of data. Additionally, just about every aspect of the existing structure was measured. Therefore, there was no need to return to the field to remeasure something not part of the original scope of services or missed in the original survey.

Wilson & Associates used a Leica C10 scan station to scan the bridge and Leica CloudWorx in conjunction with MicroStation to post process the point cloud data. We delivered as-built plans with the necessary elevations and dimensions to precast or cast-in-place the reconstructed bridge components, and we are currently providing layout. Clicking on the link below you will see Wilson & Associates’ 3-D pdf generated using our laser scanner data.